Earthing Safety Items: Essential Components for Electrical Safety

Earthing, also known as grounding, is a critical aspect of electrical safety, ensuring that in the event of a fault, electrical currents are safely dissipated into the ground. This process protects both people and electrical equipment from potential hazards such as electric shock, fires, and equipment damage. Proper earthing is essential for both residential and industrial environments. In this comprehensive guide, we will explore the importance of earthing, the various earthing systems, and essential earthing safety items.

The Importance of Earthing

Earthing provides a path of least resistance for electric currents to flow into the ground, preventing the buildup of voltages that could lead to electric shock or fire. Here are some key reasons why earthing is crucial:

- Safety: Protects humans from electric shocks.

- Equipment Protection: Prevents damage to electrical appliances and systems.

- Fire Prevention: Reduces the risk of fire caused by electrical faults.

- Voltage Stabilization: Maintains a consistent voltage level in electrical systems.

- Lightning Protection: Safeguards buildings and equipment from lightning strikes.

Types of Earthing Systems

There are several types of earthing systems, each designed for specific applications and environments. Understanding these systems is essential for choosing the appropriate earthing safety items.

- TT System: In this system, the earth connection of the electrical installation is independent of the earth connection of the utility provider. It is commonly used in rural and residential areas.

- TN-S System: The earthing and neutral conductors are separate throughout the installation. This system is typically used in older installations.

- TN-C-S System: Combines the neutral and earth conductors into a single conductor in parts of the system. It is the most common earthing system in modern installations.

- IT System: The electrical system is isolated from the earth or connected through a high impedance. This system is used in environments where continuity of supply is critical, such as hospitals.

Essential Earthing Safety Items

To ensure effective and safe earthing, several safety items are essential. These items help establish, maintain, and monitor the earthing system, providing protection against electrical hazards.

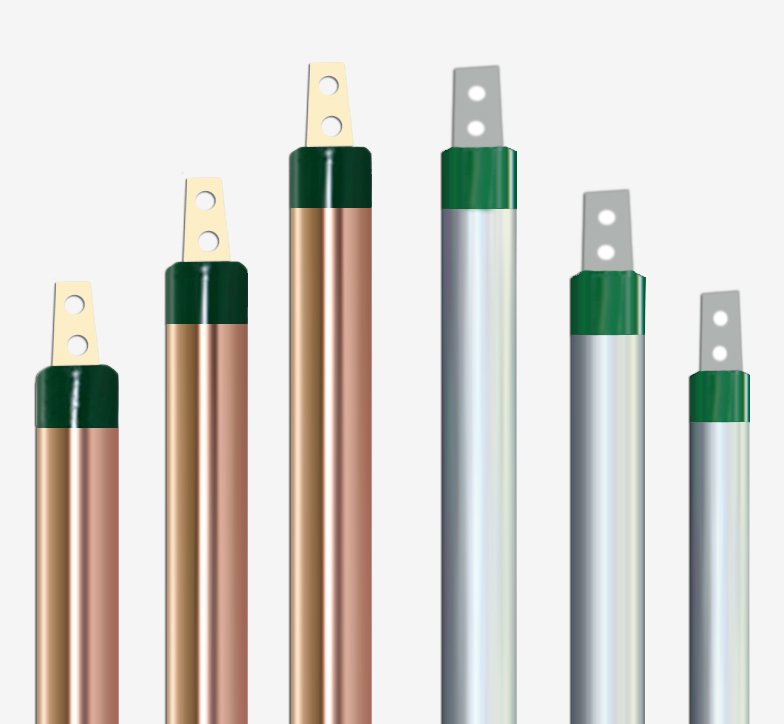

1. Earthing Electrodes

Earthing electrodes, also known as ground rods, are metal rods driven into the ground to provide a direct path for electrical currents to disperse safely. Common types include:

- Copper-Bonded Rods: Highly conductive and resistant to corrosion.

- Galvanized Steel Rods: Cost-effective but less durable than copper.

Stainless Steel Rods: Used in corrosive environments due to their high resistance to corrosion.

2. Earth Conductors

Earth conductors connect the electrical system to the earthing electrode. They are typically made of copper or aluminum and must be properly sized to handle potential fault currents.

3. Earthing Clamps

Earthing clamps are used to secure the earth conductors to the earthing electrodes and other conductive parts. They ensure a stable and secure connection, which is crucial for effective earthing.

4. Earth Pit Covers

Earth pit covers protect the connection points of earthing electrodes from environmental damage and unauthorized access. They are usually made of concrete or plastic and provide easy access for maintenance.

5. Earthing Compounds

Earthing compounds, such as bentonite or conductive concrete, are used to enhance the conductivity of the soil around the earthing electrodes. This is particularly useful in areas with poor soil conductivity.

6. Earth Leakage Circuit Breakers (ELCBs)

ELCBs detect earth faults by monitoring the current flowing in the earth conductor. If a fault is detected, the ELCB disconnects the electrical supply, preventing electric shocks and equipment damage.

7. Grounding Mats

Grounding mats provide a large surface area for dispersing electrical currents into the ground. They are used in areas where driving ground rods is impractical, such as rocky or urban environments.

8. Lightning Protection Systems

Lightning protection systems, including lightning rods and surge protectors, are essential for safeguarding buildings and electrical systems from lightning strikes. They work by providing a path for lightning currents to safely enter the ground.

9. Earthing Testing Equipment

Regular testing of the earthing system is crucial to ensure its effectiveness. Testing equipment includes:

- Earth Resistance Testers: Measure the resistance of the earthing system to ensure it meets safety standards.

- Clamp Meters: Measure the current flowing through the earth conductor without disconnecting it.

- Soil Resistivity Meters: Measure the conductivity of the soil to determine the optimal placement of earthing electrodes.

Installation and Maintenance of Earthing Systems

Proper installation and maintenance of earthing systems are vital for their effectiveness. Here are the key steps involved:

Installation

- Site Assessment: Evaluate the soil resistivity and environmental conditions to determine the best type of earthing system and the placement of earthing electrodes.

- Electrode Installation: Drive the earthing electrodes into the ground to the required depth, ensuring good contact with the surrounding soil.

- Connection: Securely connect the earth conductors to the earthing electrodes using earthing clamps. Ensure all connections are tight and free of corrosion.

- Protective Measures: Install earth pit covers and grounding mats as necessary to protect the earthing system from environmental damage and unauthorized access.

Lightning Protection: Install lightning protection systems to provide additional safety against lightning strikes.

Maintenance

- Regular Inspections: Conduct regular visual inspections of the earthing system to check for signs of damage, corrosion, or loose connections.

- Testing: Use earthing testing equipment to regularly measure the resistance of the earthing system. Ensure it meets the required safety standards.

- Record Keeping: Maintain detailed records of all inspections, tests, and maintenance activities. This documentation is essential for compliance with safety regulations.

- Soil Conditioning: If soil resistivity changes over time, use earthing compounds to improve conductivity and maintain the effectiveness of the earthing system.

Regulatory Standards and Compliance

Adhering to regulatory standards and compliance is crucial for ensuring the safety and effectiveness of earthing systems. Some of the key standards include:

- IEEE 80: Guide for Safety in AC Substation Grounding

- BS 7430: Code of Practice for Earthing

- NFPA 70: National Electrical Code (NEC)

- IEC 60364: Electrical Installations for Buildings

Compliance with these standards ensures that earthing systems are designed, installed, and maintained according to best practices, minimizing the risk of electrical hazards.

Earthing Safety in Specific Environments

Different environments have unique requirements for earthing safety. Here’s a look at some specific scenarios:

Residential Earthing

In residential settings, earthing protects occupants from electric shocks and prevents damage to electrical appliances. Key considerations include:

- Proper Installation: Ensure the earthing system is installed by a qualified electrician.

- Regular Testing: Test the earthing system periodically, especially after electrical work or renovations.

- Surge Protection: Install surge protectors to safeguard sensitive electronics from voltage spikes.

Industrial Earthing

Industrial environments have higher electrical loads and greater risks, requiring robust earthing systems. Key considerations include:

- Heavy-Duty Components: Use high-capacity earthing electrodes and conductors to handle large fault currents.

- Regular Maintenance: Conduct frequent inspections and testing to ensure the integrity of the earthing system.

- Specialized Protection: Implement additional protective measures, such as grounding mats and lightning protection systems.

Hospital Earthing

In hospitals, reliable earthing is critical for patient safety and the proper functioning of medical equipment. Key considerations include:

- Isolated Systems: Use IT earthing systems to ensure continuity of supply and minimize interference with sensitive equipment.

- Redundant Systems: Implement redundant earthing systems to ensure safety in case one system fails.

- Stringent Testing: Conduct rigorous and frequent testing to maintain the highest safety standards.

Conclusion

Earthing safety is a fundamental aspect of electrical safety, providing protection against electric shock, equipment damage, and fire hazards. By understanding the importance of earthing, the different types of earthing systems, and the essential earthing safety items, you can ensure a safe and effective earthing system for any environment.

Regular installation and maintenance, adherence to regulatory standards, and the use of high-quality earthing components are key to achieving optimal safety. Whether in a residential, industrial, or hospital setting, a well-designed and properly maintained earthing system is essential for protecting lives and property from electrical hazards. Investing in earthing safety not only enhances protection but also contributes to the overall reliability and efficiency of electrical systems.